Metallurgy

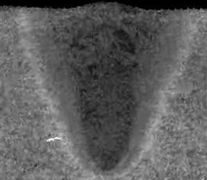

Macro

Macroscopic Examination, also called Macro Test or Macro Examination, evaluates the quality and consistency of a test sample using only low or no magnification. Macro examination of metals can be used to assess quality through the evaluation of a sample’s macrostructural features, which may include grain flow, porosity and cracks.

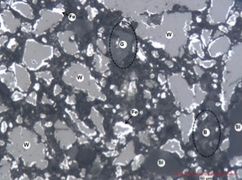

Micro

During Microstructure Analysis of metals and alloys, a Microscopic Examination is conducted to study the structure of the material under magnification. The properties of materials determine how well they’ll perform under a given application, and these properties are dependent on the material’s structure.

SEM Analysis

Scanning Electron Microscopy (SEM), also known as SEM analysis or SEM microscopy, is used very effectively in microanalysis and failure analysis of solid inorganic materials. Electron microscopy is performed at high magnifications, generates high-resolution images and precisely measures very small features and objects.

Mechanical Testing

Mechanical Testing evaluates materials under conditions such as tension, compression and temperature. Our faciltiy is equipped to provide the full range of mechanical testing services for metals and alloys with quick, reliable results and certified reports.

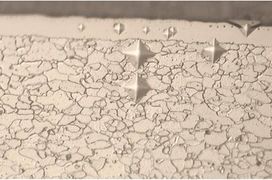

Microhardness

Microhardness Testing is a method of determining a material’s hardness or resistance to penetration when test samples are very small or thin, or when small regions in a composite sample or plating are to be measured. It can provide precise and detailed information about surface features of materials that have a fine microstructure, are multi-phase, non-homogeneous or prone to cracking.

Failure Reporting

Let our professional metallurgical test results provide insight into the nature and root cause of the failure.